3D printing vs Traditional Manufacturing

Manage episode 347565709 series 3290499

3D printing and conventional machining are often compared, especially in CNC machining and plastic molding. Engineers always consider many aspects, such as cost, lead time, capabilities, etc.

Traditional methods are reliable, versatile, and suitable for mass production. The 3D printing process is fast and grants engineers some design freedom.

It should be mentioned that 3D printing technology is additive manufacturing in contrast to traditional manufacturing processes --- subtractive ones. Let's find out which production process suits your purposes better overall.

Comparing Traditional Manufacturing vs. 3D Printing

Traditional manufacturing technology and production with 3D printers can be matched in several ways. Here are some comparison factors valid for both methods and a detailed explanation.

Simplicity and Convenience

CNC machining. It's a labor-intensive process that also requires highly specialized personnel. For one, it involves a designer of 3D models and a programmer of CAM files. It also requires engineers that would adjust the settings of a CNC unit, such as tooling, rotation speeds, feed rates, cutting paths, and more. That's before the process even begins.

Traditional manufacturing methods also require the constant presence of a skilled operator since some failures on the production line are frequent. Not to mention post-processing steps for every machined component to undergo.

3D printing. In its turn, additive manufacturing is a less labor-intensive process. It does not even require that highly-skilled labor. Only a designer/ engineer to prepare a CAD file, and you may proceed with printing right away. 3d printing can support with many types of material. You can print with plastic, metal powder and PCB prototype.

Of course, you will still have to adjust some parameters such as orientation, fill, support structures, etc. But, to be honest, every office member can be trained to use even an industrial-level printer. Supervision is not as necessary as with CNC machining as well. You may even set some additive processes on a remote, fully automated control.

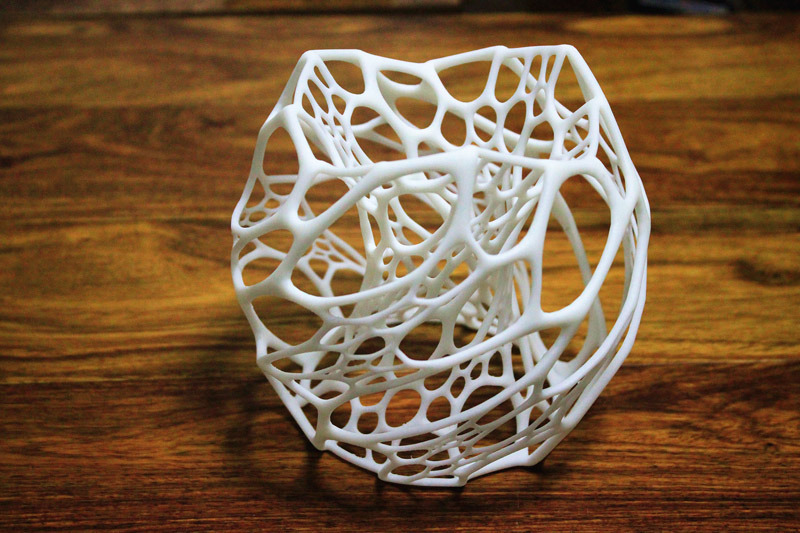

Take a look at what additive manufacturing may look like in the image below.

Accuracy and Geometric Complexity

CNC machining. What's good about traditional methods is that they can achieve extreme accuracy. But it's not always achievable because of the chatter, tooling in use, material, etc.

There are also some design constraints related to tool access, holds, square corner geometry, and more. Take it as the fact that CNC machining is not as versatile as an additive process.

3D printing. Many engineers opt for additive manufacturing because of its wide design capabilities. Industrial printers can create parts with geometries that CNC units just cannot replicate.

Additive manufacturing cannot compete with traditional machining in terms of accuracy in the present day. Constraints are printing methods, filaments in use, etc. The method is precise enough to suit most purposes.

Cost-Effectiveness

CNC mac

Powered by KISS PR Brand Story Press Release Distribution - Hosted by Qamar Zaman

438 episoder